Wow, we’ve been busy! Had some visitors and vacation time in the past couple of weeks, but we got back to building shortly after. This post encompasses ~30 hours of build work, up through priming the vertical stabilizer parts.

First up in the empennage plans is the Vertical Stabilizer. A large portion of the work involves the rear spar, to which most of the inner skeleton attaches. The spar is fairly thin, but is reinforced by “spar caps,” which are essentially doublers. The spar is pre-punched, but the spar caps require match drilling.

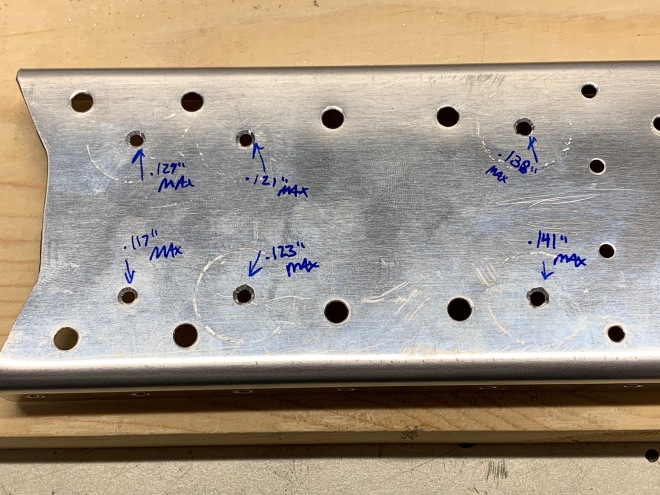

After match drilling, the plans call for countersinking a few holes on the front and rear spars to accept flush rivets. This is where our first trouble started. I took a shot at countersinking the rear spar’s six holes that are for flush rivets to the spar caps and ended up with terrible results. We didn’t have scrap to practice on, but we do now! New VS-1203 rear spar was ordered on a Sunday and arrived by Friday.

The countersunk holes chattered on me quite a bit (you can see the rough edges above). Turns out that it is difficult to get a nice countersink for the AN3 rivets when the sheet metal is at or near minimum the required thickness. Van’s recommends putting a piece of scrap behind the target hole and match-drilling then cleco-ing. The is allows scrap aluminum (or wood at the very least) behind the targeted piece to guide the pilot cutter and keep it centered. The scrap sheet should help prevent chattering and enlargement of the countersunk hole.

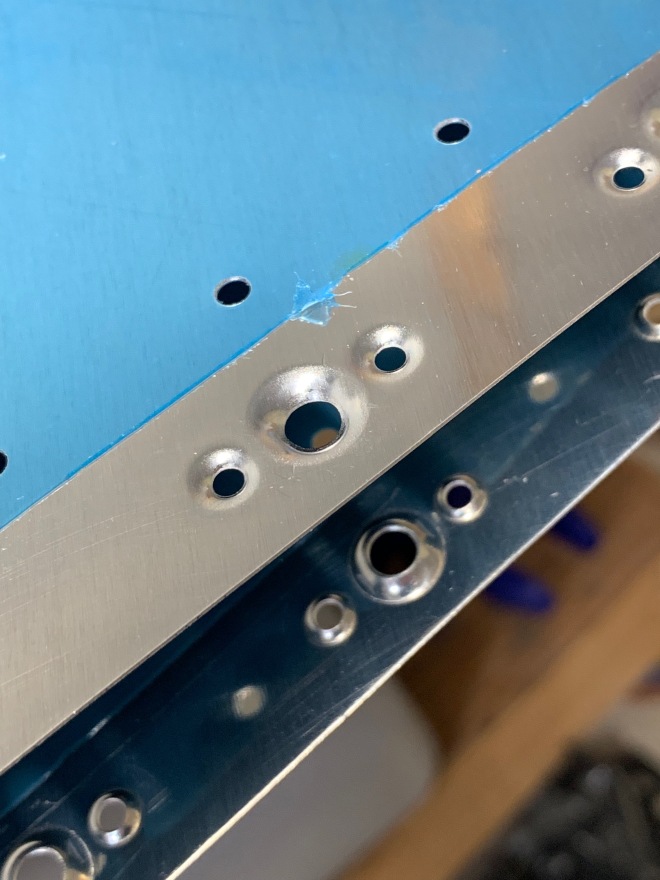

After practicing for awhile on the scrap spar (and not yet trying the above preferred methods) I still wasn’t satisfied with the success rate and asked Van’s if we could dimple the holes instead. Van’s approved, so the nutplate rivet holes on our new vertical stabilizer spar are dimpled instead of countersunk. This will require substitution of a slightly longer rivet than the plans call for since no metal was removed from the parts being fastened. Check your rivets for appropriate length before squeezing!

The ribs that attach to the spar and form the shape of the airfoil’s main skin require deburring and fluting (to straighten hole alignment) . Kelsey spent hours deburring the rib flanges and lightening holes – quite a monotonous job.

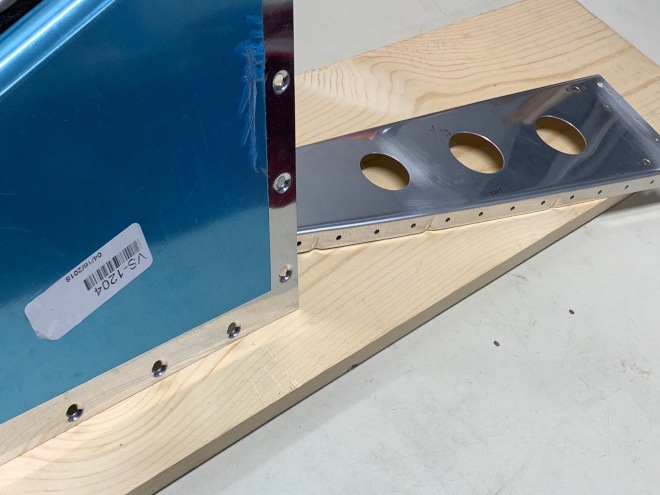

The vertical stabilizer skin consists of a main skin and a much smaller forward skin that is fastened with screws. To make the attachments flush, the skins are dimpled for the screws.

At this point, the major steps to complete the vertical stabilizer have been completed, and a test fit is in order. To do a test fit, everything is cleco’d together. If rib holes don’t align, they are fluted (or un-fluted) to line up the holes with the main skin. I’m not convinced that this ever comes out perfectly, so a tiny bit of mismatch is probably okay. Toward the leading edge, the ribs required some additional removal of material to fit inside the main skin’s pre-shaped curve. Overall, not too bad! But it takes awhile to insert and remove so many clecos!

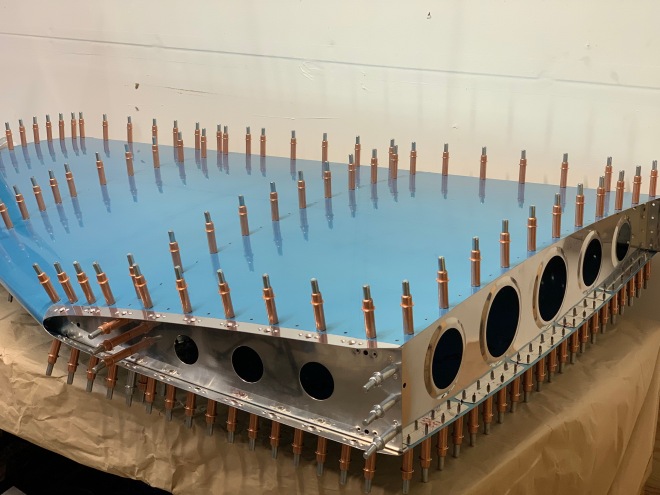

Nothing has been permanently fastened together yet because we have chosen to prime the internal structure in an attempt to prevent corrosion in the airplane’s lifetime. Priming most of the aircraft structure is not required per plans, but it can and should add additional corrosion protection. This topic is hotly debated in the experimental aircraft community, so I’ll plan to write a longer explanation about what we chose to use and how we’re doing it. For those who can’t wait: We’re using Van’s-Recommended P60G2 Sherwin Williams industrial wash primer. It does require personal protective equipment, but it dries very quickly and forms a thin protective layer.

Above are the parts after priming, with gratuitous practice paper for adjusting the spray gun.

Next up: final assembly of the Vertical Stabilizer!